On December 3rd, 2024, the Jane Addams Resource Corporation (JARC) in Chicago, Baltimore and Providence will join organizations across the globe in celebrating Giving Tuesday, a day dedicated to the spirit of generosity and philanthropy.

This year holds special meaning for us as we prepare to commemorate JARC’s 40th anniversary, and we are aiming to make this our most impactful Giving Tuesday yet!

At JARC, our mission is clear: we ensure that those who work do not live in poverty.

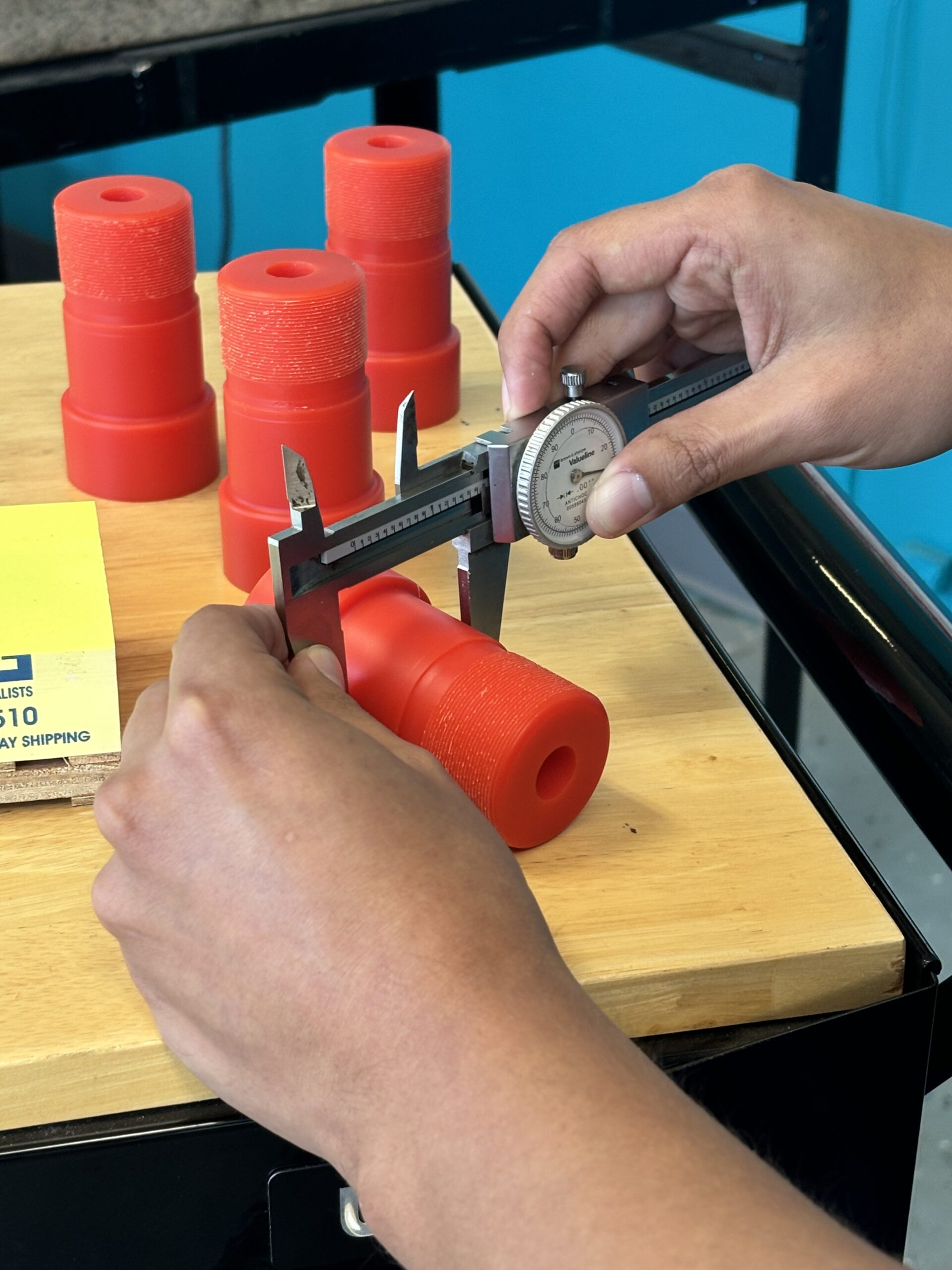

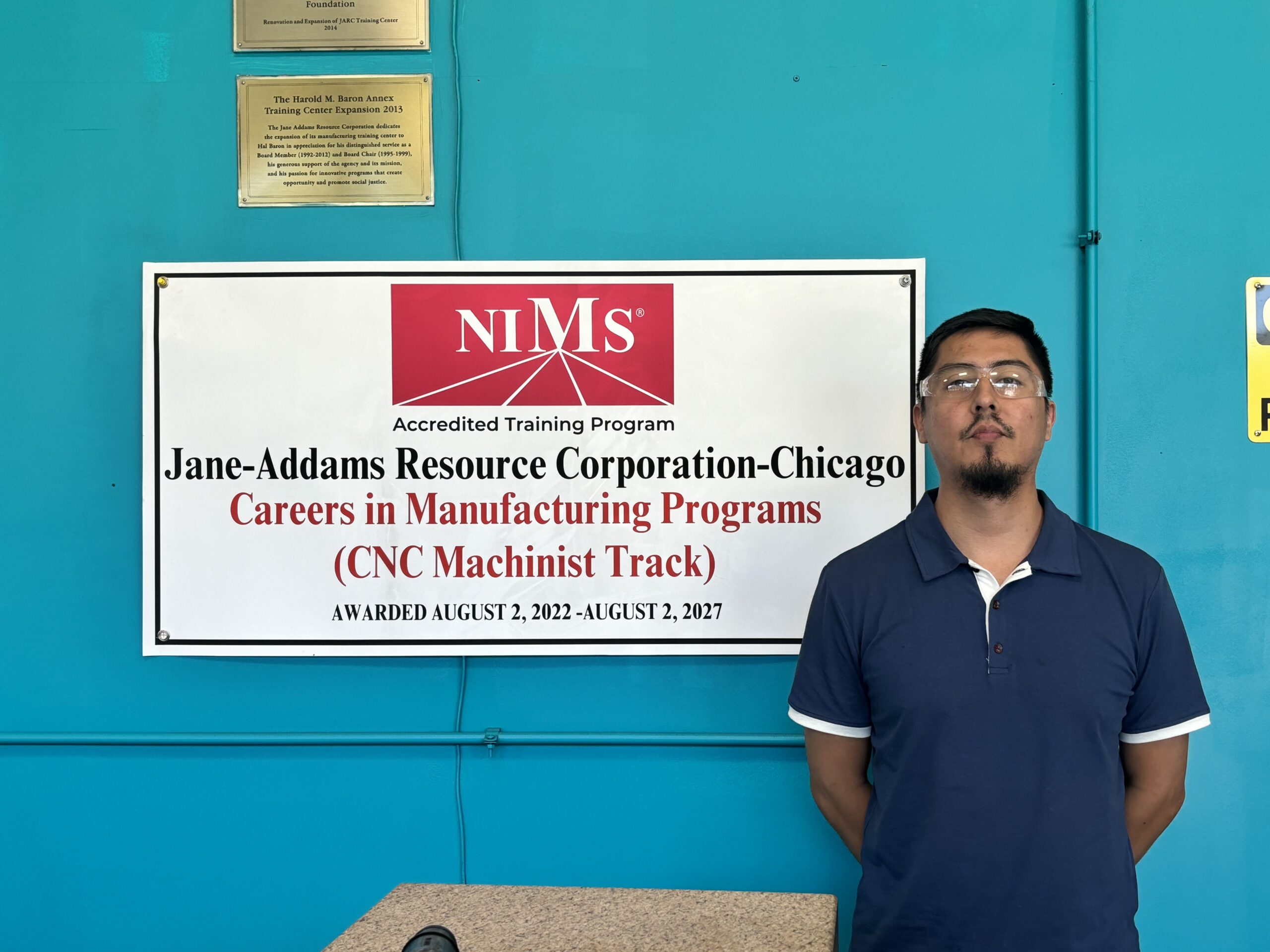

By offering free, hands-on training in high-demand manufacturing careers like welding and computer numerical control (CNC), we empower displaced and unemployed adults to build new futures. But we don’t stop at technical training. We provide vital wrap-around services, including adult literacy education, public aid application assistance, employment coaching, and financial literacy training—everything our participants need to overcome barriers and achieve success.

”"I was 36 and I wanted to make a complete career change. JARC was a life-changing experience."

Nick

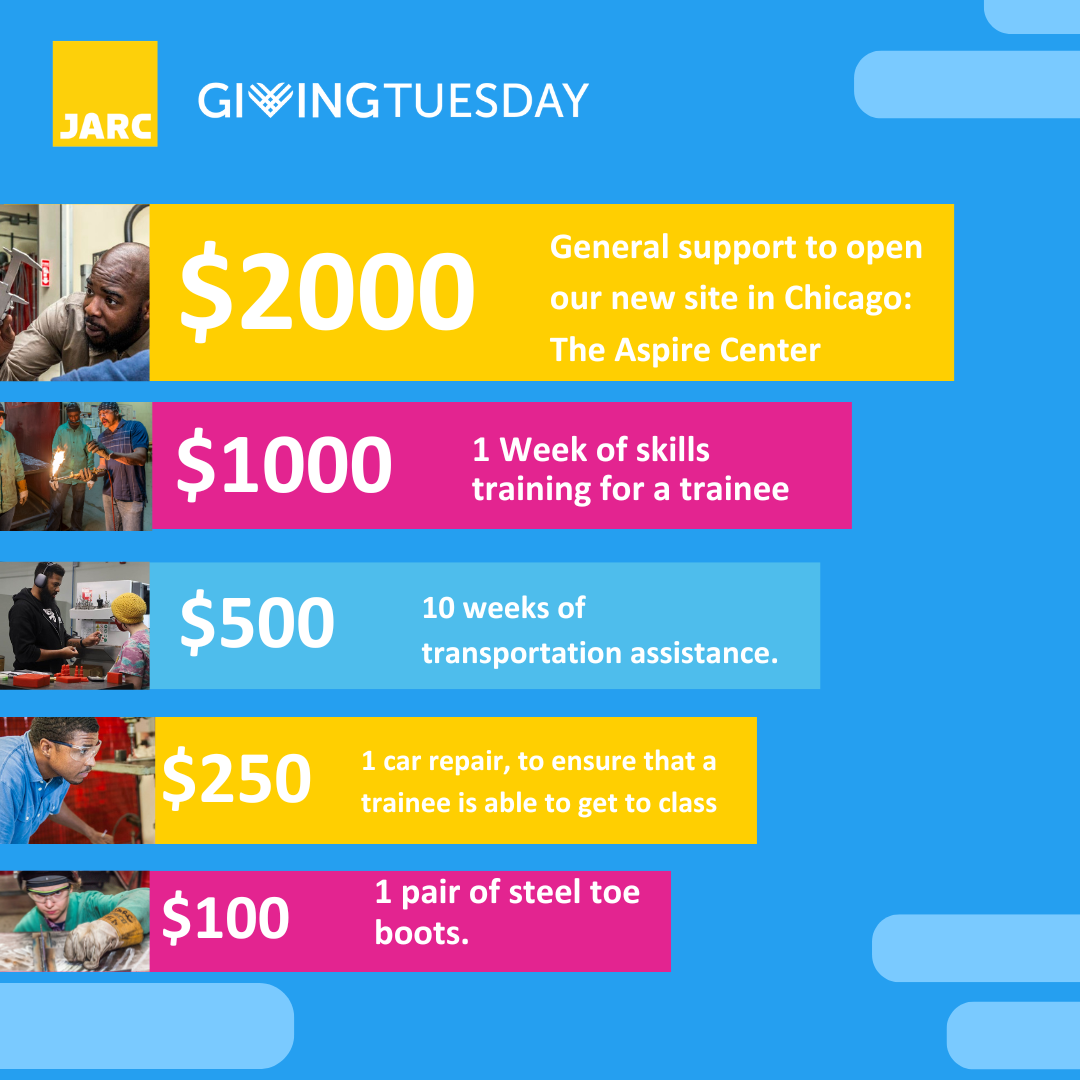

Curious how your donation will be used? Make your donation go further on Giving Tuesday!

When you choose to support JARC this Giving Tuesday, you’re not just donating; you’re becoming part of a powerful movement to lift individuals and families out of poverty. Your contribution creates a brighter, more stable future for people like Nick, one of our many participants, working to provide a better life for himself and his family.

Every dollar you give makes a tangible impact on our community. Whether it’s helping someone gain the skills they need to start a new career or offering financial coaching that sets them up for long-term success, your generosity transforms lives.

Join us in making a difference this Giving Tuesday. Click here to donate today and invest in a brighter future for all.

Thank you for believing in our mission and for supporting the work that changes lives every day!

Recent Comments