In honor of October’s Manufacturing Month, we are celebrating the importance of manufacturing, diversity in the industry, and JARC’s impact.

Photo credit: JARC

Manufacturing Month provides an opportunity to recognize the contributions that the manufacturing industry makes and create interest in manufacturing careers (Illinois Manufacturers’ Association). It is a time to acknowledge the importance of the U.S. manufacturing industry in the country’s national security and economy (U.S. Department of War), and discuss the industry’s challenges and how they might be addressed (Illinois Manufacturers’ Association).

Importance of Manufacturing

By industry, manufacturing is the fifth-largest employer in the country (United States Census Bureau). U.S. manufacturing employs almost 12.9 million people, provides $2.9 trillion to the country’s economy, and constitutes 11% of the country’s GDP (International Trade Administration).

In addition to the millions of jobs it creates, manufacturing increases economic growth, encourages technological progress, stabilizes supply chains, and is integral to national security (Forbes). U.S. manufacturing constitutes 60% of the country’s exports and is a significant source of the country’s innovation (U.S. Department of War).

Diversity and the Skills Gap in Manufacturing

Photo credit: JARC

For decades, the manufacturing sector has experienced hiring, wage, and promotion disparities by race and gender. In 2023, 71% of the manufacturing industry was male and 66% of the industry was white (Data USA).

One of many reasons to increase diversity in the industry is to address a skills gap. Even though U.S. manufacturing is growing, from 2024 to 2033, approximately 1.9 million—half of—open manufacturing jobs may not be filled due in part to a skills gap (Deloitte). Diversity, equity, and inclusion (DEI) efforts may be able to contribute to filling such roles (United States Census Bureau).

JARC’s Impact

Photo credit: JARC

JARC promotes strong communities, businesses, and households to ensure that people who work do not live in poverty, and provides high quality skills training and support services to help lower-income and unemployed workers achieve self-sufficiency (JARC).

Our organization serves adults with limited skills who are unemployed or underemployed, and our Careers in Manufacturing Programs are completely free. The programs we offer are project-based and vetted by employer partners to ensure they meet industry standards. Training is conducted in a simulated work environment, so trainees learn workplace policies and norms while acquiring technical skills. Courses are taught by industry-experienced instructors and include job placement assistance. Trainees also earn industry-recognized credentials. Our programs not only equip participants with technical and soft skills for stable careers but also support their families, taking a two-generational approach to building community wealth.

Between FY20 and FY24, JARC has graduated 213 individuals from our training programs in Chicago. In FY25, we served 174 individuals (graduates and trainees) and enrolled 62 new trainees in the Careers in Manufacturing Program. Over the last five years, JARC has achieved an 85% placement rate for program graduates, which reflects our strong focus on preparing trainees for entry level in-demand careers in manufacturing. Last year, graduates from our Welding and Computer Numerical Control (CNC) programs had an average starting wage of $20.79 per hour. Based on our data, the retention rate during the first 90 days of employment is around 68%.

JARC is committed to improving racial and gender equity in the workforce system by providing services that support communities and individuals who have been historically under-represented in manufacturing due to systemic racism, sexism, and other forms of discrimination. Our organization is dedicated to supporting women, minorities, and justice-involved individuals in gaining the skills and credentials needed to enter and succeed in the manufacturing workforce. In FY24, 78% of trainees at JARC were people of color, and 21% were female. Also in FY24, the majority of our clients were from communities facing economic hardship, with 83% living below the poverty line. Over the past five years, 70 trainees who completed our program had experience with the justice system, highlighting our commitment to serving individuals who face barriers to employment.

JARC makes a significant positive impact on the lives of our trainees and graduates.

Before discovering JARC, Toncé faced significant challenges. Her past created barriers that made finding stable, traditional employment difficult. Enrolling in JARC’s Welding program, Toncé committed herself to reinventing her life.

JARC’s comprehensive support was instrumental in Toncé’s transformation. After completing the program, she secured a job at Freedman Seating as a robotic welder. With the foundation she built at JARC, Toncé continued to grow, eventually starting her own business, Restored and Delivered Cleaning Company LLC.

Today, Toncé is thriving, both professionally and personally. She attributes her resilience and adaptability to the skills and confidence she gained through JARC’s program. “JARC was definitely my springboard that catapulted me to where I am now,” she says.

Toncé

JARC Chicago Welding Program Graduate

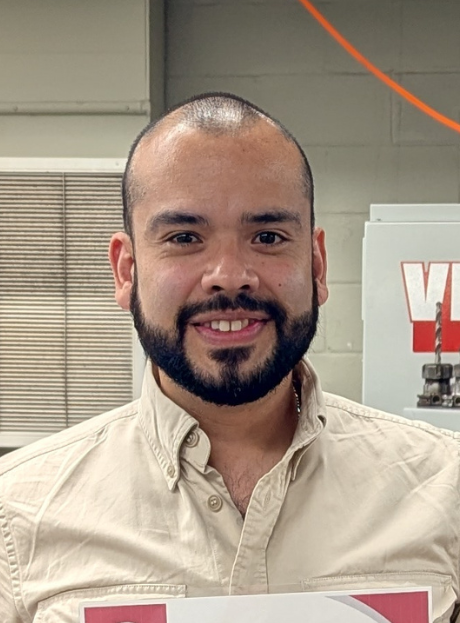

Raul

JARC Rhode Island CNC Program Graduate

In 2022, Raul immigrated from Colombia to the United States. Before joining JARC, he faced significant financial struggles.

After becoming JARC Rhode Island’s first graduate, Raul landed several interviews and received more than four job offers with the support of JARC’s Employment Coach and partners at Polaris MEP. He accepted a CNC machinist position at East Bay Manufacturers, where he has been employed ever since, earning $21 per hour.

Raul says, “JARC is a big family.” Throughout the program, his self-confidence grew significantly, and he felt that the instructors truly cared about the students. “Now, I feel like I have more opportunities and doors opening for me. I’m unstoppable,” Raul shares.

When Felipe first arrived in the United States, he worked in restaurants, starting as a dishwasher and gradually moving up to become a general manager. Looking for a change, Felipe explored opportunities that aligned with his background in mechanical engineering.

Felipe graduated from the CNC program and is now thriving in his new career as a CNC Machine Operator at Pace Worldwide, earning $24 per hour. The stability and satisfaction of this role have transformed his life.

Reflecting on his journey, Felipe calls his experience at JARC Baltimore a true stepping stone: “It [JARC] opens doors and prepares you for success in a new career.” Thanks to JARC, Felipe has transitioned from uncertainty to a career he enjoys, a testament to the power of dedicated training, supportive staff, and a clear path to opportunity.

Felipe

JARC Baltimore CNC Program Graduate

Events and Resources

Date and time:

- Thursday, November 6th, 2025 3:00 PM – 5:00 PM CT

Location:

- Total Wireless, 5601 W Belmont Ave, Chicago, IL 60634

Career Fair: Veterans in Manufacturing. Attention Veterans! Ready to launch your next career? Join us for the Veterans in Manufacturing Career Fair!

Explore in-demand manufacturing careers with JARC and learn about employment assistance through National Able’s Veterans Forward Program. Hear from a JARC Veteran trainee about their inspiring career in Manufacturing, connect with veteran support organizations, and network with fellow service members.

🎁 Get a $25 gift card when you apply and complete the interview process (while supplies last)!

Notable Manufacturing Organizations

Learn More About

JARC

Learn about our programs.

Discover our locations.

Visit our blog for success stories, events, news, and more.

Celebrate 40 years of JARC’s impact by purchasing items designed by JARC trainees and grads! Each purchased item helps fund free training and support services.

Sources

- Data USA – Manufacturing

- Deloitte – 2025 Deloitte Manufacturing Trends: From a Workday Lens

- Deloitte – Taking charge: Manufacturers support growth with active workforce strategies

- East Bay Manufacturers

- Forbes – The Importance of Manufacturing to the U.S. Economy

- Freedman Seating

- Illinois Manufacturers’ Association – October is Manufacturing Month

- International Trade Administration – Manufacturing Month

- Jakub Zerdzicki via Pexels

- JARC

- JARC – About us

- Manufacturing USA

- Pace Worldwide

- Pexels

- Polaris MEP

- The Manufacturing Institute

- The National Association of Manufacturers

- Triton College Manufacturing Expo Event

- U.S. Department of War – U.S. Manufacturing Ecosystem Key to Economic Growth, Innovation, Competitiveness

- U.S. Economic Development Administration – Reflections on Manufacturing Month, Part 1

- United States Census Bureau – How Does Manufacturing Compare to Other Industries?

- United States Census Bureau – Manufacturing Faces Potential Labor Shortage Due to Skills Gap

- Veterans Career Fair

Recent Comments