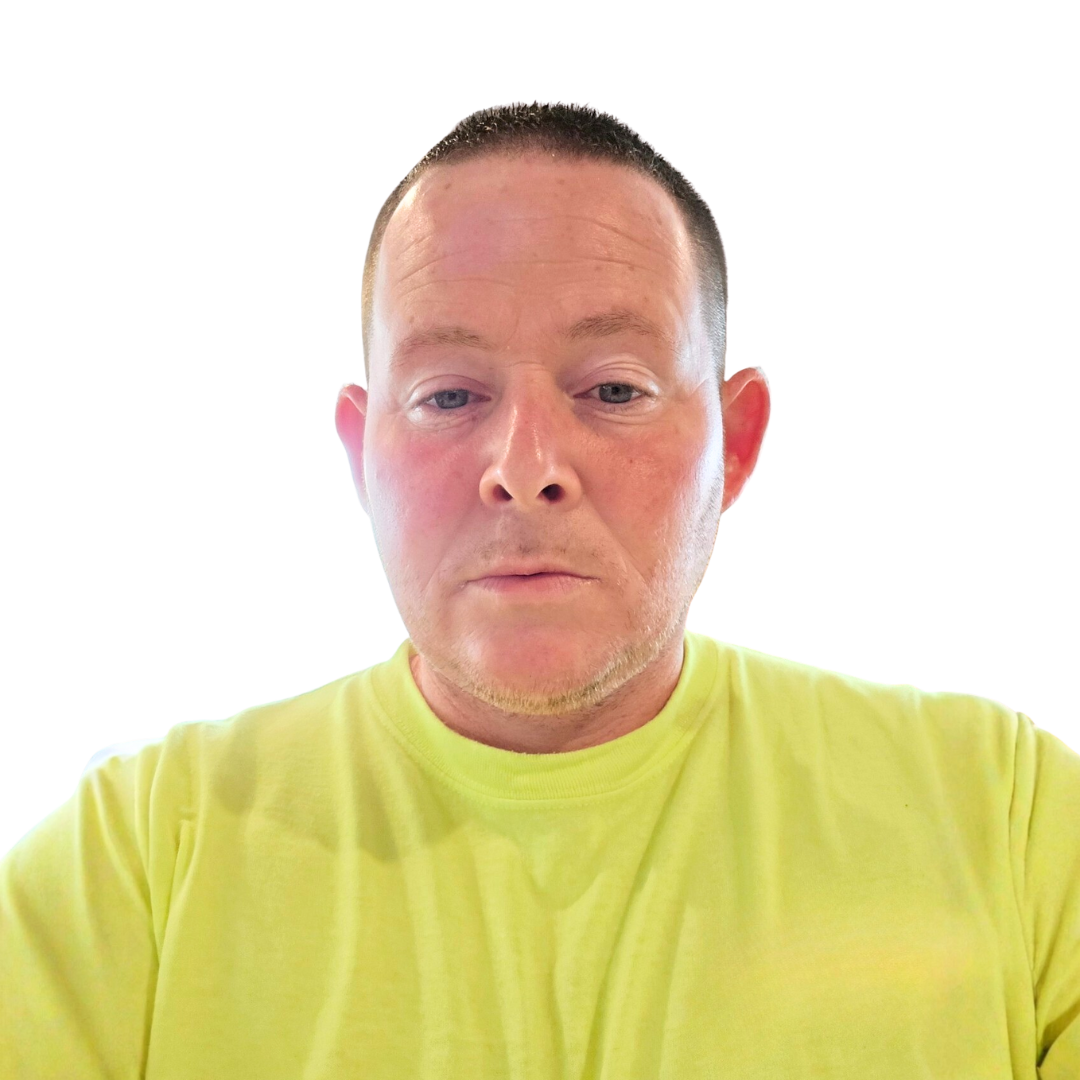

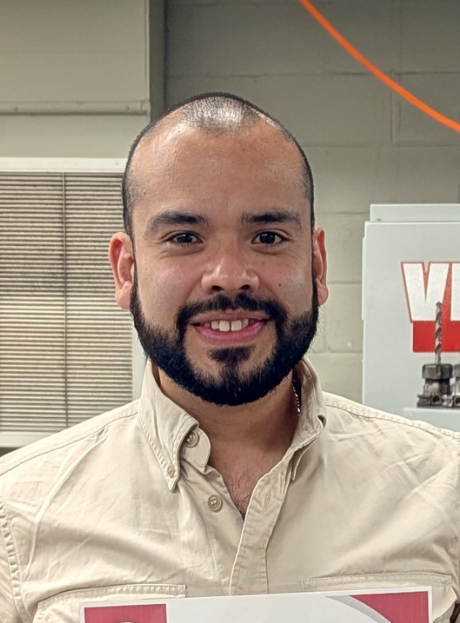

Before Mario found JARC Baltimore, life was uncertain. After a work injury at a seasonal factory, he was laid off and took on odd jobs to get by. “Before that I was working in a seasonal factory. I had an on-the-job, work injury, so they laid me off.” When a friend told him about JARC, he decided to give welding a try. “I liked what I was hearing, and I jumped on it,” Mario recalls. Expecting book work, he was surprised to find hands-on training that he loved. “When I saw the hands-on, I automatically fell in love with it because that’s the type of stuff I like to do, working my hands, and I can build stuff, break it down.” His instructors, Miss Kay and Miss Synnamin, provided crucial guidance. “They did a wonderful job helping me better understand everything, fusion of metal, the machines, everything.”

”JARC Baltimore to me means family... They go out their way to make sure students are good in all aspects, personal and school-wise.

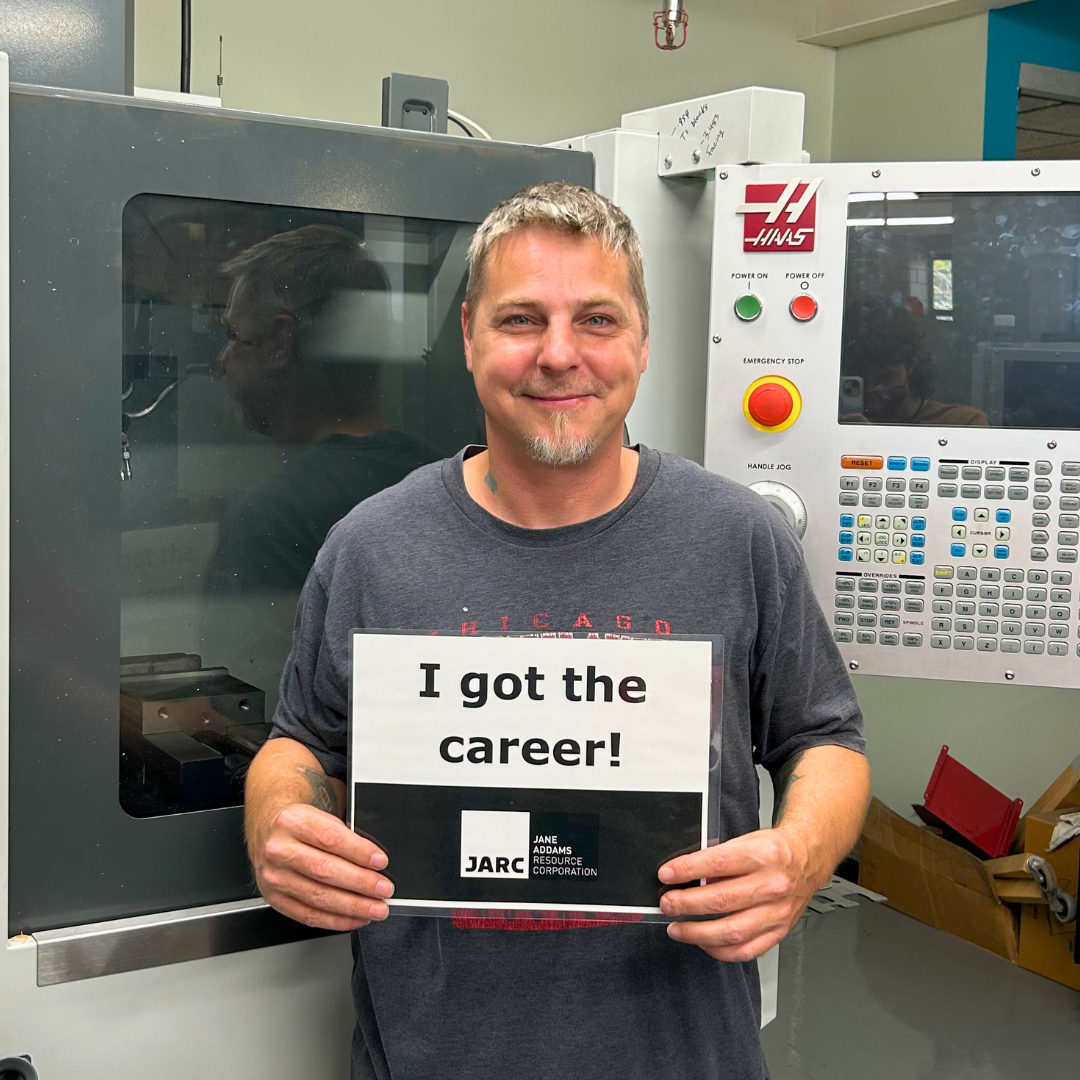

MarioWelding Graduate at JARC Baltimore

”When I saw the hands-on, I automatically fell in love with it because that’s the type of stuff I like to do, working my hands

MarioWelding Graduate at JARC Baltimore

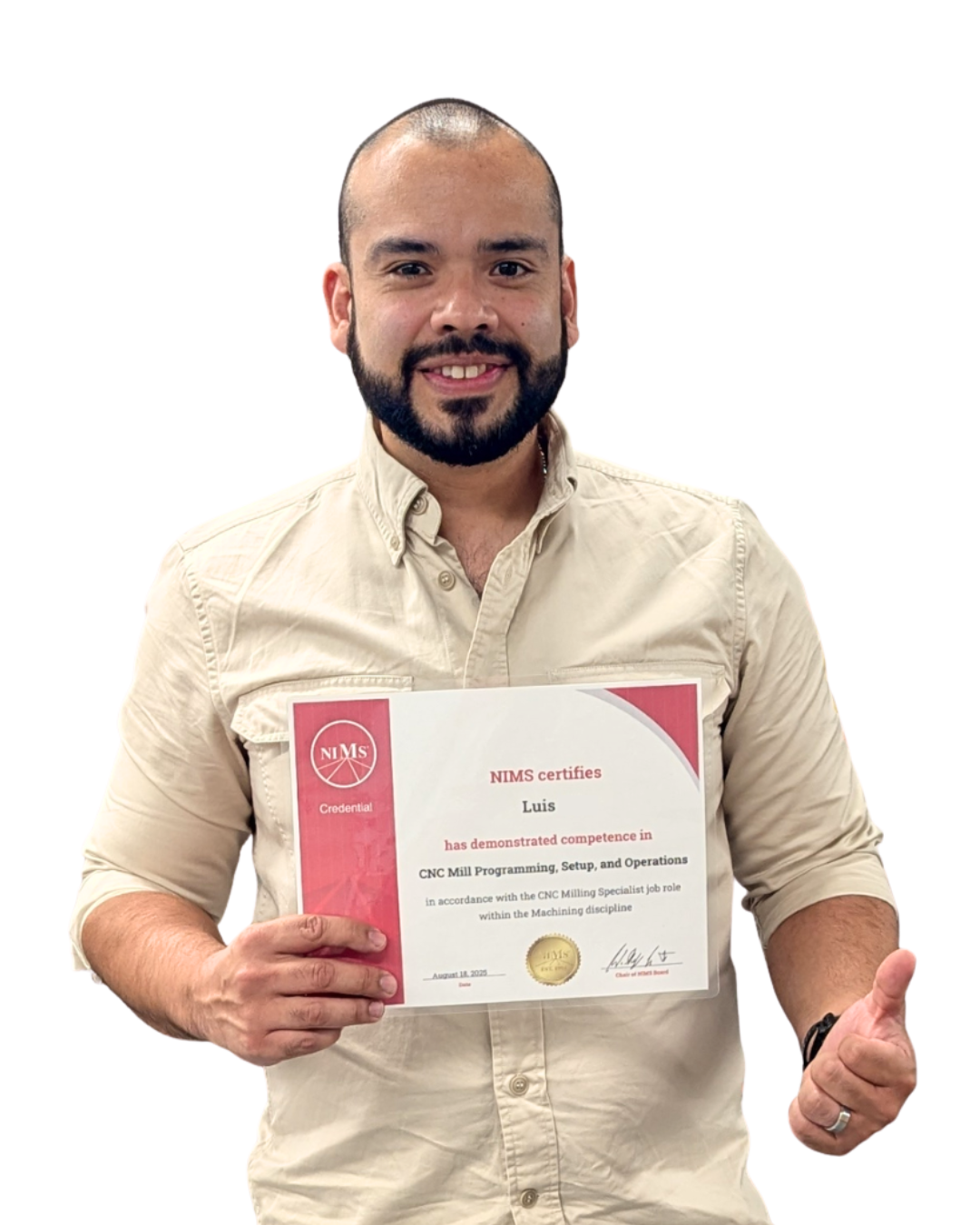

Although the first two weeks were nerve-wracking for Mario, he stayed focused and committed. “Once I really took a step back, listened to my teachers, and tried what they suggested, after that it was smooth sailing.” His dedication paid off: “I passed certification the first test plate I sent through.” Support at JARC went beyond training. “Everyone was wonderful. If I needed help with questions, anything about school or personal, people went beyond their measures to make sure not just me, but everyone was taken care of.” Mario even helped fellow students, calming frustrations and offering hands-on help. During his time at JARC, he received 17 income support sessions, along with one-on-one coaching in employment and finance. He also participated in 26 workshops focused on financial literacy, job readiness, and educational growth.

After graduation, JARC’s job placement team helped Mario find welding opportunities.

Despite some setbacks, he persevered. A call from Brian Miller at Local 219 changed everything: “I just got a phone call from Mr. Brian saying, ‘meet me here,’ and the next day I was a career apprentice with Western Industrial Union Local 219 making $17.60/hr.”

Now, five months in, Mario is thriving as a pre-apprentice welder and assembler, earning over $18.54 per hour. “I love it because I see all this working in my hands… Western has good people who don’t criticize you and are willing to help if you don’t know.” Mario’s life has improved in many ways. “Financially, physically, it did wonders. I bought another car, so I got two cars, me and my wife. Physically, I’m getting stronger from the heavy lifting.” He also treasures diversity at work. “I love meeting different people from other states and parts of the world, learning their culture and language.”

When asked what JARC means to him, Mario says without hesitation: “JARC Baltimore to me means family… They go out their way to make sure students are good in all aspects, personal and school-wise.” His advice to others is simple: “You must be willing to put the time and effort into it because they expect the same commitment from you that they give to teach us. Just show up on time, be willing to learn, and have a good attitude.” Thanks to JARC, Mario isn’t just building metal structures; he’s building a stable, fulfilling career.

Recent Comments