On December 2nd, 2025,

Jane Addams Resource Corporation (JARC) is joining organizations around the world in celebrating philanthropy.

As JARC commemorates our 40 years of impact, we are striving to make this year’s campaign more successful than ever. Your support will help us reach our goal of raising $15,000 and make a meaningful difference in our trainees’ lives!

With this year’s funding challenges, we are relying more than ever on people like you to support us!

A huge shout-out and heartfelt thank you to our incredible Leader Sponsor at Freedman Seating Company for their generous support in matching our Giving Tuesday donations!

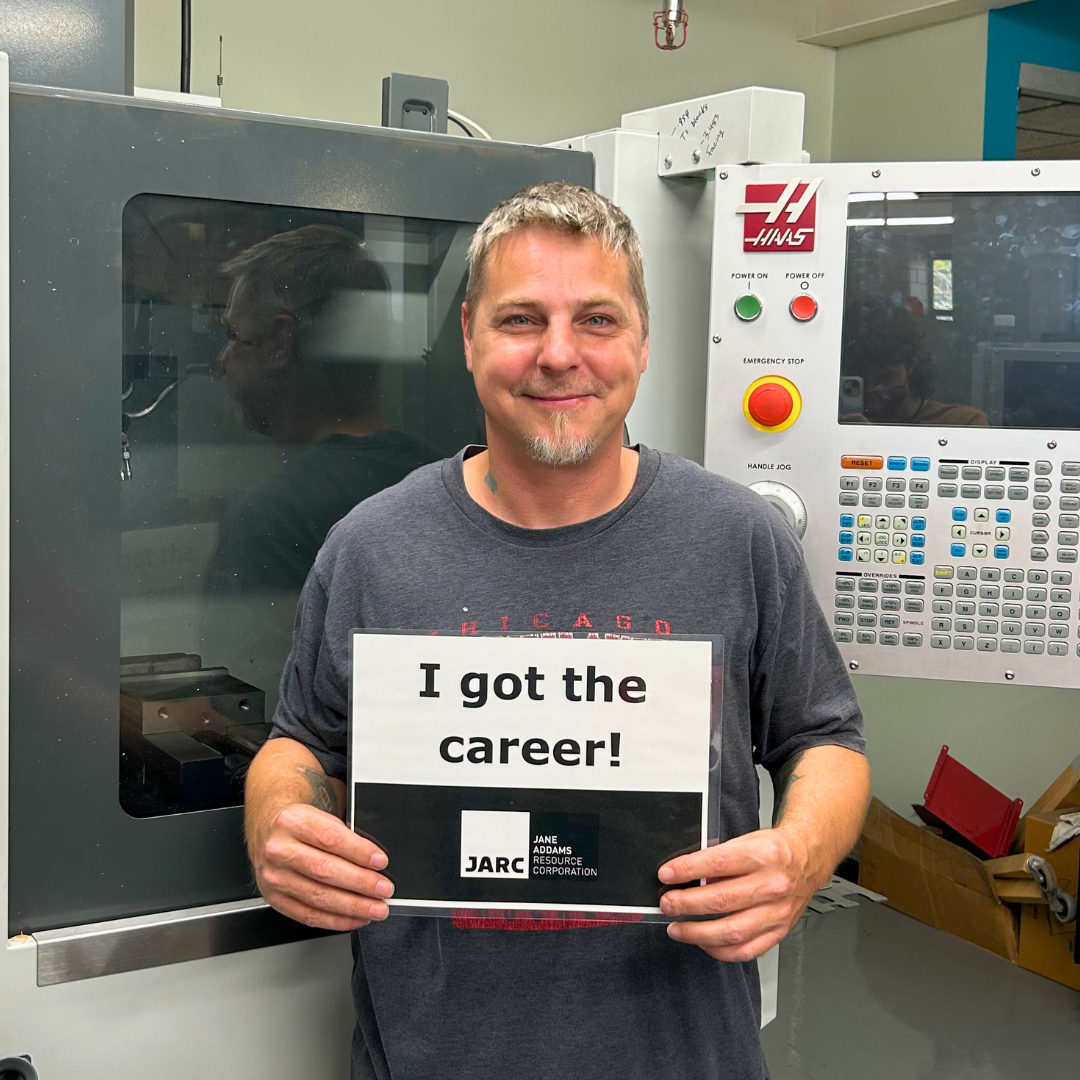

At JARC, we ensure that those who work do not live in poverty.

We do this by offering free training for careers in manufacturing like Welding and Computer Numerical Control, focusing on lower-income and unemployed adults. We also provide wrap-around supportive services such as adult literacy education, public aid application assistance, employment coaching, and financial coaching.

”“JARC was definitely my springboard that catapulted me to where I am now.”

Toncé, JARC Chicago Welding Program Graduate

Before discovering JARC, JARC Chicago Welding Program Graduate Toncé faced significant challenges. Her past created barriers that made finding stable, traditional employment difficult. Enrolling in JARC’s Welding program, Toncé committed herself to reinventing her life.

JARC’s comprehensive support was instrumental in Toncé’s transformation. After completing the program, she secured a job at Freedman Seating as a robotic welder. With the foundation she built at JARC, Toncé continued to grow, eventually starting her own business, Restored and Delivered Cleaning Company LLC.

Today, Toncé is thriving, both professionally and personally. She attributes her resilience and adaptability to the skills and confidence she gained through JARC’s program. “JARC was definitely my springboard that catapulted me to where I am now,” she says.

This Giving Tuesday,

here are some ways that you can support us in sustaining our programming and mobilizing people out of poverty:

Donate now at your level of choosing—every dollar makes a difference! Support a specific area of our work that speaks to you, such as funding one week of hands-on manufacturing training, buying a pair of steel-toe boots for a new trainee, or helping design and create JARC’s first-ever mascot!

Thanks to our generous sponsors this year, your donation will be matched dollar for dollar up to $7,500, doubling the impact of your gift!

Enter Our Giveaway!

All donations over $100 enter to win a limited-edition mug and donations over $500 enter to win a limited-edition tote bag and mug. These items are designed by our trainees and graduates!

Visit our store and purchase our limited-edition t-shirts and mugs designed by our trainees and graduates! Every purchase helps us reach our goal, and fund free training and support services. Wear their story, fuel our mission!

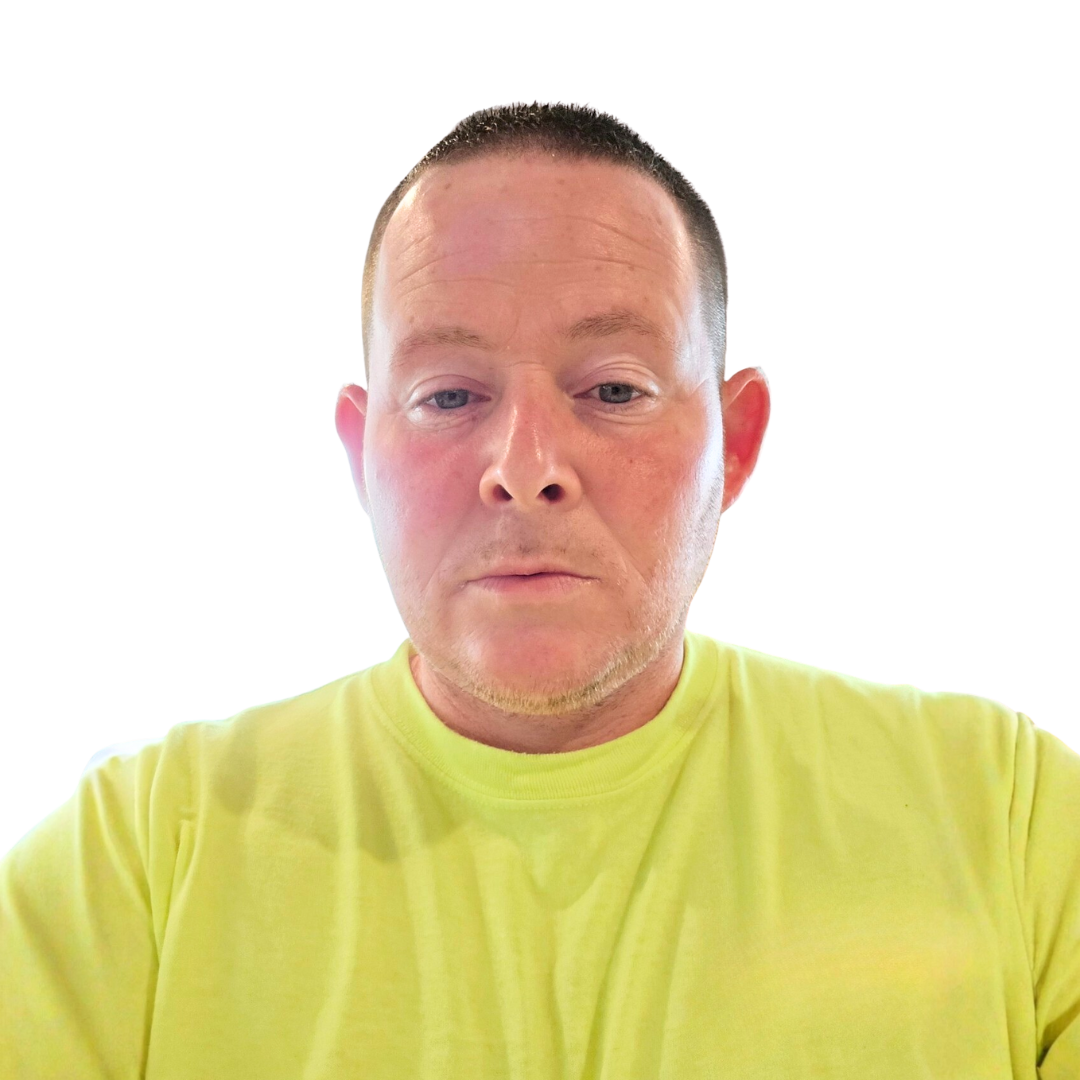

Christopher, JARC Chicago Welding trainee, with his winning design!

Thank you to our generous

matching sponsors!

If you have any questions, please contact us at development@jane-addams.org. We appreciate your consideration and hope you will join us in celebrating this special day!

Important: All donations are designated as General Operating funds to support JARC’s programs and services. While we’ve included examples of what contributions at different levels could help achieve, individual gifts are not earmarked for specific items or programs. Your support helps us continue serving our trainees and community in the areas of greatest need.

Recent Comments